OptiFuel™ is a concentrated fuel additive comprised of a fuel-soluble carrier containing several catalysts that, combined, act to improve combustion efficiency and reduce emissions. OptiFuel can be blended with fuel at any point from fuel manufacturing to the end user filling their vehicle’s tank.

OptiFuel™ is a concentrated fuel additive comprised of a fuel-soluble carrier containing several catalysts that, combined, act to improve combustion efficiency and reduce emissions. OptiFuel can be blended with fuel at any point from fuel manufacturing to the end user filling their vehicle’s tank.

OptiFuel is suitable for use in gasoline, gasoline/ethanol blends, diesel, biodiesel, diesel/biodiesel blends, and residual fuels such as bunker fuel. It can also be added to fuels such as wood chips to improve BTU values and reduce emissions.

What does OptiFuel do?

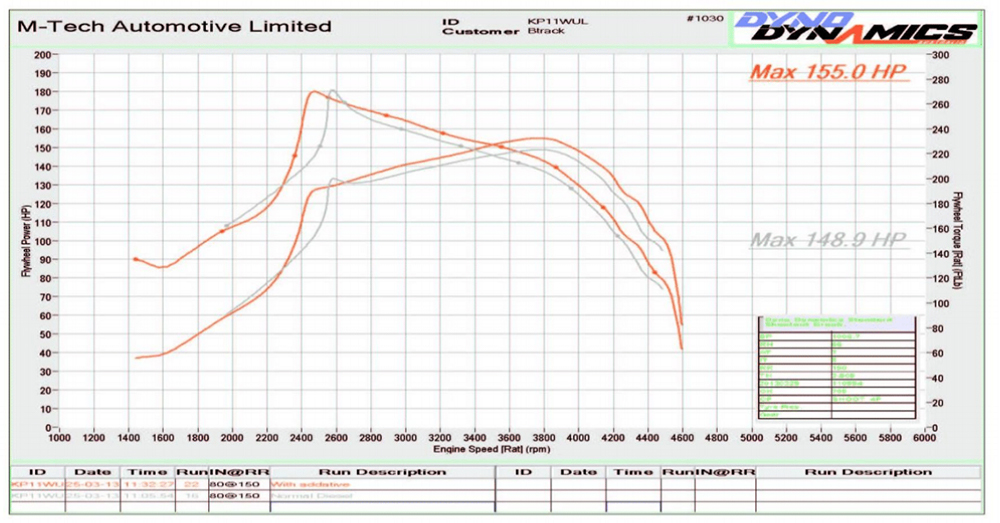

OptiFuel catalytically reduces harmful emissions, improves engine torque, and improves fuel consumption.

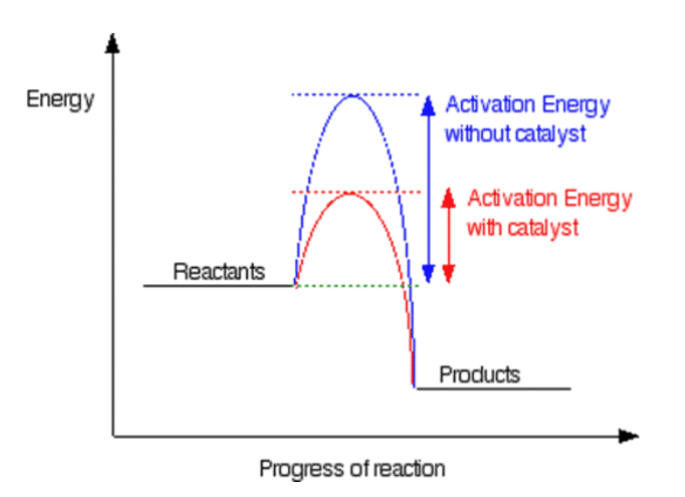

Certain components in OptiFuel reduce activation energy during the combustion process. Activation energy is the amount of energy required to initiate a chemical reaction, which, in this case, is the reaction of oxygen free radicals with hydrocarbon fuel. The reduction in activation energy during combustion is achieved via addition of catalysts in the fuel that are carried by the fuel into the engine during operation. The catalysts do not cause combustion to occur, they simply facilitate the combustion reaction once combustion is initiated in the engine cylinder.

During fuel combustion in a closed system such as an engine’s cylinder, activation energy is not recoverable as work output, so a reduction in activation energy during fuel combustion translates to more system energy available to do work. This is commonly seen as an improvement in torque with a concomitant improvement in Specific Fuel Consumption (SFC), which is a measure of the amount of fuel needed to perform a specific amount of work, such as moving X mass Y distance. In the case of generators, SFC is usually measured as the amount of fuel needed to generate a kilowatt-hour of energy.

Because SFC is improved, less carbon as Carbon Monoxide (CO) and Carbon Dioxide (CO2) is emitted when measured against work performed.

The catalysts provided during the combustion process also contribute to the reduction of carbon emissions measured as soot or Particulate Mass (PM) in engine exhaust due to improved combustion efficiency.

OptiFuel also has catalysts in it that work post-combustion to reduce emissions. The catalytic process by which OptiFuel reduces NOX and SOX is similar to Selective Catalytic Reduction (SCR) units. That said, OptiFuel does not have the same shortcomings that SCR does, where SCR only becomes effective once the system reaches a sufficient temperature for catalysis to occur, which is typically between about 250°C and 430°C. OptiFuel also is not subject to catalyst “poisoning” (a reduction in catalytic effectiveness due to reaction with chemicals that impede the catalytic effect). Nor does the user have to be concerned with about thermal cycling breaking down the physical structure of their catalytic converter over time. This is because the active catalysts are being continually supplied in the fuel.

OptiFuel does not change the characteristics of the fuel it is blended into, so a fuel that meets national/international fuel standards prior to blending with OptiFuel still meets those standards.